MDF Information

What is MDF?

MDF (Medium Density Fibreboard) is an engineered wood-based sheet material, primarily consisting of wood fibre particles bonded with resin and wax. It is generally manufactured in panels using heat and pressure.

MDF is normally a favoured material in the building industry, as being man-made, it does not suffer from natural defects associated with soft and hard wood like; warps, twists, shakes, splits or knots. This makes it an easier and more economical material to work with, and ideal for a large array of applications.

Various types of MDF have emerged over the years to cater for different purposes including moisture resistant, fire retardant and extreme MDF (for external use) to name a few. Differences in type are related to the density of the board.

What MDF Do We Use?

Over the years we have specifically refined the specification of the MDF we use to a Higher Density, Moisture Resistant MDF. This material is specified as it is far denser and less permeable than a standard or premium MDF, used by other manufacturers. Used in conjunction with Tungsten Carbide tipped cutters, this superior material allows us to create a cleaner moulding on all of our skirting and architrave products.

Don't just take our word for it, order a free MDF skirting board sample and check it out for yourself.

Why Is A Higher Density MDF So Important?

The density of MDF is critical in gaining a good finish on skirting and architrave for several production reasons.

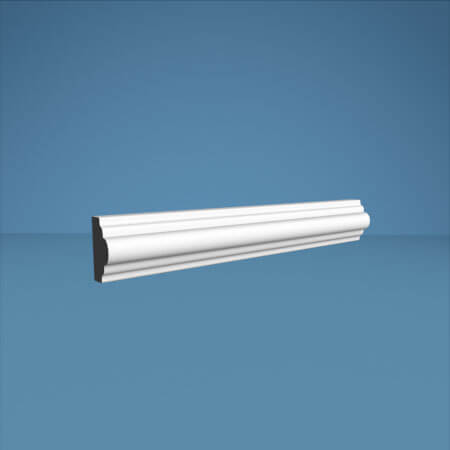

Moulding

When MDF is cut to put the shape on a skirting board, the cut surface will feel rougher than the rest of the board. This is because removing part of the board leaves the softer core of the board exposed. The cut pulls the remaining surface fibres from this softer core upwards. This is part of the rough texture and is called furring. If surface fibres are displaced this also means the surface they have been displaced from is less even, which also contributes to a rough texture.

Furring reduces the greater the density of the fibre board because more fibres are compacted together under greater pressures. This means that proportionately, less fibres will stick up from the core, making the surface less porous, and more even. Essentially the denser the board, the cleaner and smoother the cut will be.

Painting

MDF density is also important in gaining a good spray finish on the moulded part of a skirting board. Lower density fibre boards are manufactured with less fibre particles, under reduced pressures. This creates a softer core, which is full of minuscule cavities and makes the board far more porous. When sprayed this porous board will absorb far more paint than a higher density board, on which paint will settle on the surface more easily, producing an easier, cleaner finish on our MDF skirting boards and MDF architrave.

Should Moisture Resistant MDF Be Green?

Initially Moisture Resistant (MR) MDF was manufactured with a green dye so it could be easily identified, however industries that paint MDF find the green colour harder to cover and and in response to growing demand for undyed board, MDF manufacturers now produce MR MDF either with or without dye.

Today there is a mix of dyed and un-dyed in the market place with each MDF manufacturer offering differing panel dimensions either dyed or un-dyed ex stock. As such MR MDF may appear in one of three appearances:

Dyed:

Part Dyed:

Undyed:

.png)